Startseite » Maschinen » alphaFLOW®BASIC

Das Herzstück jedes Filtrationsproduktes ist die Filtermembran.

Vor der Freigabe für die Anwendung muss diese einen streng überwachten Integritätstest erfolgreich bestehen – insbesondere bei Medizinprodukten.

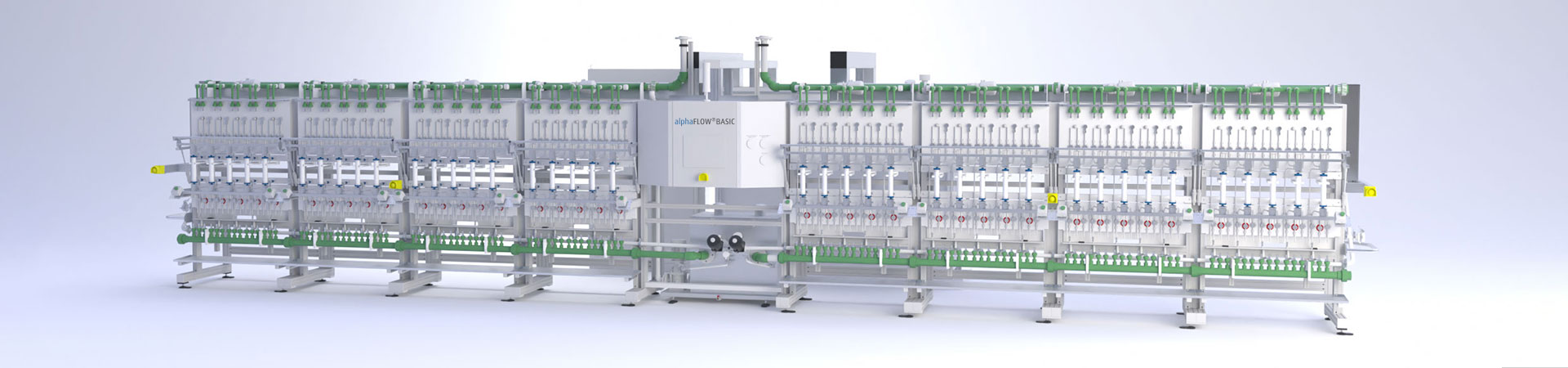

Die alphaFLOW®BASIC gewährleistet eine zu 100 % zuverlässige Prüfung der Produktion. Dabei wird die Filtermembran mit hochreinem Wasser auf Dichtigkeit geprüft. Die Tests erfolgen membranschonend und fehlerhafte Produkte werden zuverlässig separiert.

Hinweis: Die Variante alphaFLOW®PRO vereinigt die Prozesse der alphaFLOW®BASIC und der alphaMICRO®. So decken Sie mit einer Maschine alle Prozesse ab und müssen nicht zusätzlich noch die alphaMICRO® installieren.

BASIC | PRO | |

|---|---|---|

| 100 % Prüfung auf Membranintegrität | ||

| Integrierte automatische Anlagensanitisierung (Heißdampf) | ||

| BDE-System | ||

| Vollautomatische Sterilisation | ||

| Trocknung der Produkte direkt nach Nassprüfung | ||

| Vollautomatische Be- und Entladung sowie Zuführung der Produkte mittels Transportsystem und Robotertechnik |

alphaFLOW®BASIC – im Einsatz. Erfahren Sie mehr im Video!

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren